Our technicians undergo training from field representatives of equipment manufacturers, ensuring they possess exceptional knowledge about the equipment they operate.

01

Glass Cutting

Our two new fully automated CNC glass cutting lines provide straight-edge and shape cutting, have scanning capability, and handle glass sheets up to 130″ x 236″ with thicknesses ranging from 1/8 to 3/4″.

02

Double Edge Polishing

Our horizontal double-sided automated edge polish machine line accommodates extra-large glass up to 131″x236″, with rapid cycle times and considerable processing capacity. We offer flat polishing as well as mitered edges and beveled edges.

03

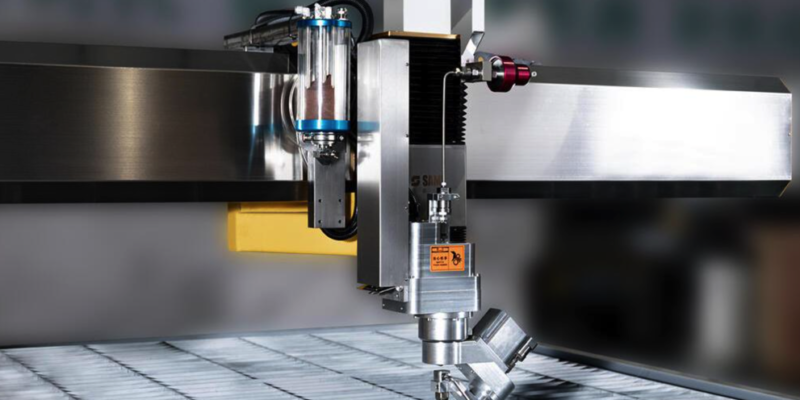

Water Jet cutting

Our Water jets can be used for a variety of glass cutting applications, including cutting intricate stained glass to piercing holes in glass. Water jets can be used to cut through any thickness of glass available and any shape of glass with CAD drawing.

04

CNC Cutting

CNC machining allows us to cut custom shapes to precise tolerances and perform specialty milling & drilling with pinpoint precision. This technology is commonly used in the glass industry for producing glass panels, windows, doors, and other glass components with customized shapes and sizes.

05

Notching & Drilling Holes

Our automatic drilling machine provides holes up to 4 inches for most of your installation needs, such as shower doors, glass railings, glass entrance doors, tabletops, etc.

06

Laminating Glass

Crafted with precision and care, our kilns are designed to deliver laminated glass with outstanding safety properties for a wide range of applications. Our laminating oven features innovative fast curing and cooling, and is capable of processing EVA, PVB, and SGP films with glass sizes up to 98×196.

07

Flat Glass Tempering

Flat glass tempering is a process used to strengthen and enhance the durability of flat glass panels. During this process, the glass is heated to a high temperature and then rapidly cooled, which creates internal stresses. These internal stresses increase the strength of the glass, making it more resistant to breakage and thermal stress. Flat glass tempering is commonly used in the production of architectural glass for windows, doors, partitions, and other applications where safety and durability are important.

08

Bending Glass Tempering

Bending glass tempering, also known as curved glass tempering, is a process used to strengthen and shape glass into curved or bent forms while maintaining its durability. During the tempering process, the glass is heated to a high temperature and then rapidly cooled. This creates internal stresses that give the glass increased strength and resistance to breakage. Bending glass tempering allows for the production of curved glass panels used in architectural applications such as curved windows, glass railings, and facades.

09

Insulated Glass Units

Our automatic Insulating line features edge deletion, automatic argon filling, and automatic sealing all in one line. Our insulating line is capable of virtually any unit thickness, size, and glass configuration, including high-performance argon-filled double or triple pane units requiring high-performance soft-coat Low-E coatings, We also stock a large selection of spacers with different colors. Our standard units utilize desiccant-filled aluminum spacers and are dual-sealed with a butyl primary seal and a structural silicone secondary seal.

10

Sandblasting

Sandblasting is essentially the process of blasting the surface of a glass with grit which peppers the surface, giving it a milky white appearance. Sandblasting is like to paint on glass. Every design is possible in sandblasting.

11

Heat Soak Furnace

The heat soak furnace can heat the surface of tempering glass to reach stress homogenization and avoid safety hazards such as inner stress or self-explosion, which increases the safety and reliability of tempered glass.

12

Delivery

We offer delivery to the jobsite throughout NYC and Long Island. We can deliver to nearby areas such as upstate New York, New Jersey, Connecticut, Pennsylvania, and Massachusetts, or arrange third-party delivery services in order to reach our customers nationwide. Speak to one of our customer service representatives for pricing and details.